Liquid Metal And Inkjet Printers Could Usher New Era Flexible Circuits For Wearable Tech

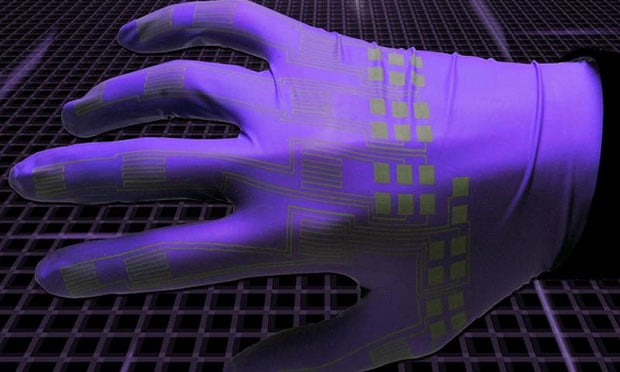

If it hasn't been proven obvious enough up to this point, the wearables market has immense potential, and we're not just talking about things like smartwatches or smart eyewear. What about shirts? Gloves? Hats? For a number of different reasons, smart clothing could prove very useful, or down-right important, depending on who's wearing it. But there is a problem with such implementations: integrated circuits typically don't like to be bent.

We've seen bendable displays time and time again, but what about bendable ICs? That could become possible if printing circuits with liquid-metal alloys becomes a common thing - and researchers at Purdue University hope that proves to be the case.

A research paper on this technology is to be published in the April 18th issue of Advanced Materials, and it'll describe how liquid alloys could be printed to materials with ordinary inkjet technology. Because these alloys are too thick to be pushed through inkjet nozzles, the researchers have found a way to use ultrasound to break the material into nanoparticles, effectively solving that issue.

Printing isn't enough to have this liquid alloy act as a circuit, though. Once printed, light pressure needs to be applied to to rejoin all of the nanoparticles, which then makes the substance conductive. It's noted that this is required because when the liquid alloy is turned into nanoparticles, it develops a skin of oxidized gallium which prevents electrical conductivity.

There's still a lot of work to be done in researching this method, but so far the implementation and execution sounds good. If it does become a reality, it'd result in wearables that can be stretched and bent without a loss of signal, and the mere idea of that is pretty exciting.