Stanford Researchers Discover Ultra-Thin Semiconductor Materials That Promise Huge Gains In Chip Transistor Density

When it comes to electronics, semiconductors make the world go round. This has been true for many decades, though future generations will own devices with different physical makeups than those that are in use today. That includes a potential move away from silicon. In what could be a glimpse into the future, electrical engineers at Stanford have identified a pair of ultrathin semiconductor materials that are every bit as good (and perhaps better) than silicon.

Those materials are called hafnium diselenide and zirconium diselenide. Like silicon, these materials can "rust" in a way that is conducive to electronics. In fact, the researchers say they rust in a manner that is even more desirable than silicon. That is because they form what are called "high-K" insulators, which allow for lower power operation than what is possible with silicon and its silicon oxide insulator.

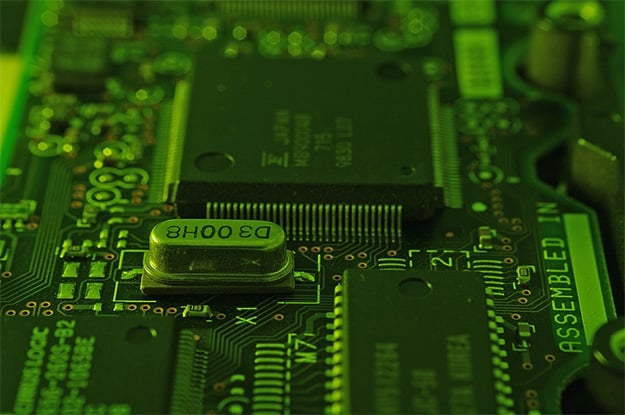

Image Source: Stanford via Michal Mleczko

The above image shows an enlarged cross-section of an experimental chip made with one of the newly discovered semiconductor materials. Alternating layers of hafnium diselenide (the ultrathin semiconductor material) and the hafnium dioxide insulator comprise the black and white bands. The cross-section matches an overlaid color schematic on the right.

What is also neat about these materials is that they can be shrunk down to functional circuits measuring a mere three atoms thick. They also require less energy than silicon circuits. The Standford engineers are optimistic that these materials could lead to the kind of thinner and more energy efficient chips that future devices will require.

For now, silicon is the material of choice. Part of the reason is because it has a very good "native" insulator, silicon dioxide (silicon rust). During the manufacturing phase, silicon is intentionally exposed to oxygen so that chip makers came more easily isolate their circuitry. Other types of semiconductors do not rust when exposed to oxygen, so they have to be manually layered with insulators. That comes with additional engineering challenges and costs. However, both of the materials discovered by the Stanford researchers form this desirable layer of rust when exposed to oxygen.

"Engineers have been unable to make silicon transistors thinner than about five nanometers, before the material properties begin to change in undesirable ways," said Eric Pop, an associate professor of electrical engineering who co-authored with post-doctoral scholar Michal Mieczko a paper on the subject.

Thinner circuits with high-K insulation ultimately means that these utlrathin semiconductors would be formed into transistors 10 times smaller than anything that is possible with today's silicon. Of course, there are challenges that stand in the way. The electrical contacts between transistors on ultrathin diselenide circuits need refined. Researchers are also working to better control the oxidized insulators so that they remain as thin and stable as possible.