Toshiba, Samsung Argue Over The Future of 3D Flash

The burgeoning SSD (solid state drive) market has been a modest success story over the past few years. Drive performance and capacity have both increased at a fair clip, while initial sky-high costs have at least fallen into the stratosphere. The two major factors keeping sSD's from broader market penetration are available capacity and cost. Both have dropped dramatically in the past year, but when an Intel 160GB MLC SSD sells for $629 and the most expensive 2TB drive on the market is just $299, a number of customers who are interested in SSDs will ultimately buy a standard hard drive based on cost alone.

Both Toshiba and Samsung are working on manufacturing technologies that would allow NAND cells to be stacked on top of each other rather than aligning them horizontally; Toshiba hopes to have cost-effective products on the market by 2013. Samsung hasn't given a projected date for its own design completion, but the companies are backing two distinctly different 3D manufacturing techniques. Toshiba has demonstrated a prototype 32Gb drive that's built in three dimensions, a fact that hopefully indicates that high-capacity SSDs could be on the market in a reasonable amount of time.

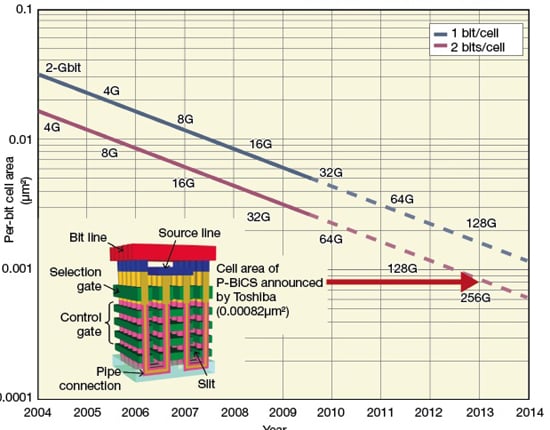

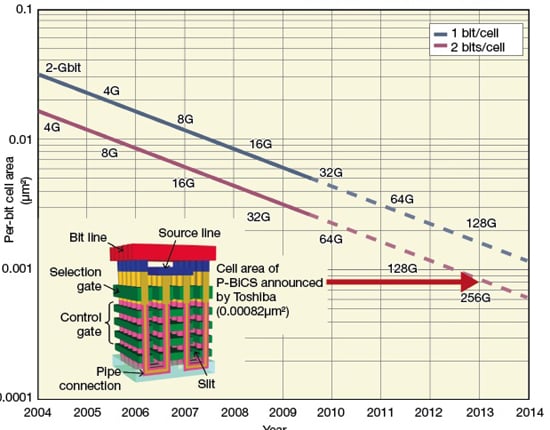

The potential benefits of 3D NAND cells far outweigh concerns over which company's solution will prove most effective. At vLSI this year, Toshiba demonstrated the aforementioned 32Gb 3D NAND module built on an older 60nm process. The fact that the cell was built three-dimensionally allowed Toshiba to stack two bits of data per cell, with a total cell area approximately equivalent to a hypothetical Flash cell built on a 20nm process. 3D stacking could also be used to push the reliability and performance of SLC (single layer cell) drives into MLC territory.

Based on the graph, Toshiba believes its 3D technology could enable the rollout of much larger drives at a fraction of the cost. If companies with older foundries can utilize 3D cell technology to build NAND flash, it helps level the playing field between themselves and the mere handful of corporations worldwide that can afford to transition their fabs to ever smaller (and ever more expensive) processes. 3D flash is cheaper, possibly faster, and definitely more dense. Only downside is, it's still five years away, at best. If Samsung or Toshiba's research into 3D cell technology

pays off, it could mark the beginning of an assault on the one feature HDD's are expected to retain in the near future—capacity.

Both Toshiba and Samsung are working on manufacturing technologies that would allow NAND cells to be stacked on top of each other rather than aligning them horizontally; Toshiba hopes to have cost-effective products on the market by 2013. Samsung hasn't given a projected date for its own design completion, but the companies are backing two distinctly different 3D manufacturing techniques. Toshiba has demonstrated a prototype 32Gb drive that's built in three dimensions, a fact that hopefully indicates that high-capacity SSDs could be on the market in a reasonable amount of time.

The potential benefits of 3D NAND cells far outweigh concerns over which company's solution will prove most effective. At vLSI this year, Toshiba demonstrated the aforementioned 32Gb 3D NAND module built on an older 60nm process. The fact that the cell was built three-dimensionally allowed Toshiba to stack two bits of data per cell, with a total cell area approximately equivalent to a hypothetical Flash cell built on a 20nm process. 3D stacking could also be used to push the reliability and performance of SLC (single layer cell) drives into MLC territory.

pays off, it could mark the beginning of an assault on the one feature HDD's are expected to retain in the near future—capacity.